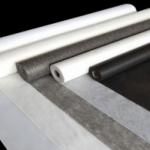

Interlining (known also as Fabric Stabiliser) is an intermediate layer that attaches two fabrics to each other by using different methods that provide the needed hardness and smooth appearance to the clothes, adding quality to the fabric.

Many of you buy the products you like from the leading brands in the ready-made clothing industry, but we do not have much information about how these products are sewn and by which methods/details they become a whole.

Interlining, which is frequently used in trouser pieces and collars and shirt cuffs, is used in different areas. Usage areas may differ according to the needes hardness and softness.

Interlining, which gives volume and hardness to the treated fabric, gives shape to the garment and provides support to the fabric in washing, ironing and all processes that it may encounter, ensuring that it does not lose its volume and achieves the desired appearance.

Fabric interlining obtained from nonwoven products has many types according to the fabric bonding types. Heat-bonded interlinings of one of these types are cost-effective soft-resistance interlinings used in soft tissues. The latter are interlinings bonded with chemical bonding and are products used in processes such as hard durable belts and emriodery.

Woven interlinings, on the other hand, are interlinings that are generally used in coats, jackets and outwear products to give a beautiful appearance in front of the chest and neck, and these vary in terms of fibers, yarn thickness, weaving structure, fabric weights and weaving density.

Knitted interlinings, on the other hand, are interlinings mainly used in outwear products and there are types in the form of plain knit, circular knit, warp knit.